Welcome to the comprehensive guide on the transformative world of vineyard management, where the innovative Vineyard Tying Machine takes center stage. This article explores how this cutting-edge technology revolutionizes viticulture, enhancing efficiency and quality in vineyards. From small family-run estates to expansive commercial vineyards, discover how the Vineyard Tying Machine is reshaping the industry, making viticulture more efficient, precise, and sustainable. Dive into a detailed exploration of the various types, key features, economic aspects, and the crucial role of choosing the right machine for your specific vineyard needs.

In the ever-evolving world of viticulture, technology has emerged as a game-changer, revolutionizing traditional practices and introducing efficiency and precision. One such technological marvel is the Vineyard Tying Machine, a tool designed to support vineyards in maintaining optimal grapevine growth. This chapter delves into how technology, particularly the vineyard tying machine, plays a pivotal role in modern viticulture, enhancing productivity while ensuring environmental sustainability.

Traditionally, viticulture has been a labor-intensive industry, where tasks like tying and training vines were done manually. This not only consumed considerable time and effort but also posed challenges in consistency and effectiveness. The advent of technologies like the Vineyard Tying Machine has brought about a transformation, automating these critical tasks. This automation doesn't just streamline operations; it also ensures uniformity and precision that manual labor can seldom achieve.

The integration of technology in viticulture goes beyond mere mechanization. It encompasses data-driven decisions, where vineyard managers can analyze various parameters like soil moisture, weather conditions, and plant health. This data, when combined with the operational efficiency of tools like the vineyard tying machine, empowers vineyard managers to optimize growth conditions, enhance grape quality, and maximize yields, all while reducing the environmental footprint.

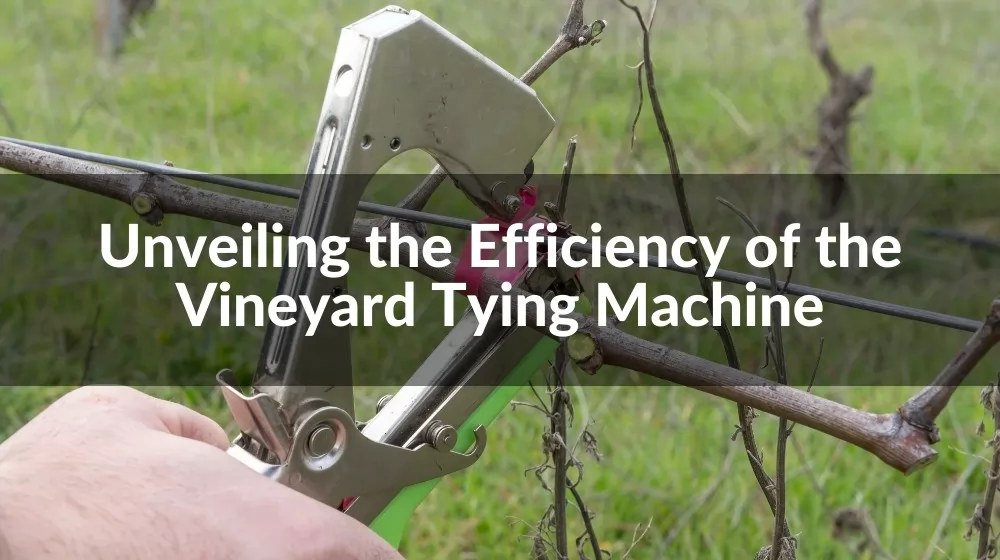

A Vineyard Tying Machine is a specialized piece of equipment designed for viticulture. This machine streamlines the process of tying vines to trellises, a critical task in vineyard management. Its primary function is to automate the tying process, which traditionally has been a manual and time-consuming task. By doing so, it significantly reduces labor costs and improves efficiency in vine care and maintenance.

The machine typically features a portable design, making it easy to carry and use throughout the vineyard. It operates by securing vines to support wires or stakes using ties or clips. This process is crucial for training and managing the growth of the vines, ensuring they receive optimal exposure to sunlight and air circulation, which are vital for healthy growth and fruitful grape production.

Furthermore, the Vineyard Tying Machine is designed to be gentle on the vines, preventing damage that can occur with manual tying. It's engineered for precision, ensuring that the ties are neither too loose, which can lead to uncontrolled growth, nor too tight, which could damage the vine. This precision contributes to the overall health and productivity of the vineyard.

The basic function of a Vineyard Tying Machine is to automate the process of securing vines to their supports. This task, while seemingly simple, is crucial for the proper training and growth of grapevines. Let's delve into the specifics of how this machine operates and the fundamental roles it plays in a vineyard's lifecycle.

Firstly, the machine is designed to efficiently tie vines to trellises or wires. It does this using a mechanism that wraps a tie around the vine and its support, then securely fastens it. This process ensures that vines are adequately supported as they grow, helping to maintain an organized and manageable vineyard. The ties used are typically made from durable materials that can withstand various weather conditions, ensuring long-term support for the growing vines.

Another fundamental function of the Vineyard Tying Machine is its precision. The machine is calibrated to apply just the right amount of pressure – enough to hold the vine in place without damaging it. This precision is crucial as too tight a tie can constrict the vine, impeding its growth, while too loose a tie may not provide adequate support.

Additionally, the machine is designed for ease of use and maneuverability. It's typically lightweight and portable, allowing vineyard workers to carry it along rows of vines with ease. This portability is a significant factor in increasing the efficiency of vineyard management, as it allows for quick and easy tying throughout the vineyard.

The evolution from manual to mechanical vineyard tying marks a significant milestone in the journey of viticulture. This transition encapsulates the industry's shift towards greater efficiency, precision, and sustainability. Let's explore this transformative journey, highlighting how the Vineyard Tying Machine has revolutionized traditional practices.

Historically, vineyard tying was a manual process, requiring considerable labor and time. Workers would move row by row, manually tying vines to trellises using twine or wire. While this method allowed for a high degree of control, it was labor-intensive, time-consuming, and often inconsistent, depending on the skill and fatigue level of the workers.

The introduction of mechanical solutions, like the Vineyard Tying Machine, marked a new era in vineyard management. These machines offered a way to standardize the tying process, ensuring consistency and efficiency. The automation of tying not only sped up the process significantly but also reduced the physical strain on workers, leading to more uniform vine growth and management.

The mechanical approach also brought about enhanced precision. The Vineyard Tying Machine is designed to apply a consistent amount of pressure and placement, something that is hard to achieve manually. This precision is crucial for the health of the vines, as improperly tied vines can lead to restricted growth or damage.

Moreover, the shift to mechanical tying aligns with the broader trend in agriculture towards sustainability. By reducing the time and labor required for vineyard management, vineyard owners can optimize resource use and reduce their carbon footprint. The machine's efficiency translates to fewer hours of operation, meaning less fuel or electricity consumption, and a reduced environmental impact.

Vineyard Tying Machines come in various types, each designed to cater to different needs and preferences within the viticulture industry. This chapter focuses on the diversity of these machines, exploring their unique features and functionalities. Understanding the various types available helps vineyard managers choose the most suitable machine for their specific vineyard conditions and management style.

One primary differentiation in Vineyard Tying Machines is based on their mode of operation. There are manual, semi-automatic, and fully automatic types, each offering different levels of automation and user involvement:

Another way to categorize Vineyard Tying Machines is based on their power source. Some machines are battery-operated, offering portability and ease of use without the need for a constant power source. Others might be pneumatic or powered by other means, providing different levels of power and efficiency for the user.

Furthermore, the design and materials used in these machines vary. Some models are designed for rugged durability, able to withstand harsh vineyard conditions, while others might focus on lightweight and ergonomic design for user comfort during extended use.

The Vineyard Tying Machine is not just a tool for automation; it is a hub of innovative features that enhance viticulture practices. This chapter will explore the key features and innovations that set these machines apart, highlighting how they contribute to the efficiency, effectiveness, and sustainability of vineyard management.

One of the most notable features of Vineyard Tying Machines is their ergonomic design. Manufacturers have focused on creating machines that are comfortable to hold and operate for extended periods, reducing operator fatigue. This ergonomic consideration is vital in ensuring that the vineyard workers can operate the machines efficiently without physical strain.

Another key feature is the precision tying mechanism. These machines are equipped with advanced systems that ensure the ties are consistently tight enough to secure the vine but not so tight as to damage it. This precision is crucial for the health and productivity of the vines.

Many Vineyard Tying Machines are also incorporating environmentally friendly materials in their ties. Biodegradable or recyclable materials are increasingly being used, reducing the environmental impact of vineyard operations and aligning with the industry's move towards sustainability.

In terms of innovation, some machines are integrating smart technology. This includes features like programmable settings, where users can adjust the tying parameters according to the specific needs of their vines. Some models even offer connectivity options, allowing for data collection and analysis, which can be used to further optimize vineyard management practices.

Another innovative aspect is the energy efficiency of these machines. Battery-operated models are designed to last longer, reducing the need for frequent recharging. This not only makes the machines more convenient to use but also lessens their environmental footprint.

The introduction of the Vineyard Tying Machine has significantly impacted vineyard operations, particularly in areas of efficiency, productivity, labor management, quality, and environmental sustainability. This chapter examines these aspects in detail, showcasing the comprehensive benefits brought by this innovative tool.

The automation provided by Vineyard Tying Machines has dramatically increased operational efficiency. Tasks that once took hours can now be completed in a fraction of the time, leading to a notable increase in overall productivity. This efficiency allows vineyard managers to allocate resources more effectively, focusing on other crucial aspects of vine management.

One of the most significant impacts of the Vineyard Tying Machine is on labor requirements. By automating the tying process, the need for manual labor is greatly reduced. This not only cuts down on labor costs but also mitigates issues related to labor shortages, a common challenge in the agricultural sector.

The precision of mechanical tying ensures that vines are supported in the most optimal way. This precise support plays a crucial role in maintaining the health of the vine, directly impacting the quality of grape production. The consistency offered by machine tying also ensures uniformity in vine growth, which is essential for high-quality grape yield.

Precision in tying directly influences grape quality. Properly tied vines have better exposure to sunlight and air, vital factors for healthy grape development. Moreover, the reduced stress on vines from appropriate tying techniques can enhance the quality of the fruit produced, leading to better wine production.

The use of Vineyard Tying Machines also has positive environmental implications. With reduced manual labor, there's less need for fuel-powered transportation in vineyards, leading to a lower carbon footprint. Additionally, the use of eco-friendly materials in the ties contributes to environmental sustainability.

Sustainability is a growing concern in viticulture, and the Vineyard Tying Machine aligns with this trend. By improving efficiency and reducing resource use, these machines help in creating more sustainable vineyard operations. Their contribution to reducing the overall environmental impact of vineyard management is an important step towards eco-friendly agriculture practices.

The economic aspects of implementing a Vineyard Tying Machine are a crucial consideration for vineyard owners and managers. This chapter delves into the cost analysis, examining purchase and operational costs, return on investment (ROI), and the long-term financial benefits associated with these machines.

Investing in a Vineyard Tying Machine involves initial purchase costs, which can vary depending on the type and features of the machine. While manual and semi-automatic machines are generally less expensive, fully automatic models may require a higher upfront investment. However, it’s essential to consider the operational efficiency and labor savings when evaluating the overall cost.

Beyond the purchase price, operational costs include maintenance, repairs, and the cost of consumables like ties or clips. These machines are designed for durability, but regular maintenance is key to ensuring their longevity and optimal performance. Operational costs are typically offset by the reduction in manual labor and increased efficiency.

The ROI of a Vineyard Tying Machine can be significant. By automating the tying process, vineyards can achieve substantial labor cost savings. Additionally, the increased efficiency and productivity can lead to higher yields and better-quality grapes, which can translate into increased revenue, especially over multiple harvest cycles.

In the long term, the financial benefits of using a Vineyard Tying Machine are manifold. These include sustained savings in labor costs, improved grape quality leading to higher market prices, and the potential for increased production capacity. Moreover, the durability of these machines means that they can provide these benefits for many years, making them a wise investment for forward-thinking vineyards.

Selecting the appropriate Vineyard Tying Machine is pivotal to achieving optimal vineyard management. This chapter offers insights into the factors vineyard owners should consider when choosing a tying machine, including the size, terrain, and specifics of their vineyard, along with a buying guide and tips for making the right purchase.

When selecting a Vineyard Tying Machine, it's essential to consider various factors such as the size of your vineyard, the type of vines you're growing, and the specific conditions of your vineyard. The choice between manual, semi-automatic, and fully automatic models should align with your operational needs and workforce capabilities.

The size and terrain of your vineyard play a significant role in determining the most suitable machine. Larger vineyards may benefit more from a fully automatic machine to manage the extensive tying workload efficiently. The terrain of your vineyard also matters; uneven or sloped terrain might require a more robust and maneuverable machine. The type of vine and the trellising system used should also be considered, as different machines may be better suited to different vine types and trellis designs.

A comprehensive buying guide should include an assessment of the machine's durability, ease of use, maintenance requirements, and compatibility with your vineyard's specific needs. It's also wise to consider the manufacturer's reputation, warranty, and customer service support.

Here are some tips for making an informed purchase:

In conclusion, the integration of a Vineyard Tying Machine is more than just a technological upgrade; it's a pivotal step towards modernizing viticulture practices. Embracing this innovation leads to improved efficiency, higher quality grape production, and a more sustainable approach to vineyard management. As a leading manufacturer in this field, Linkwin stands at the forefront of this revolution. Chinese expertise and technological innovation converge at Linkwin, offering some of the best Vineyard Tying Machines in the market. Discover more about how Linkwin is transforming vineyards worldwide and explore their range of products at www.agriculturaltool.com.

We use cookies to make the website work, to provide advanced features, social media and traffic analysis, and we use analytics and third-party advertising cookies. If you choose to click "Deny All", you will retain the default setting of not allowing the use of cookies or other tracking tools other than technical tools.